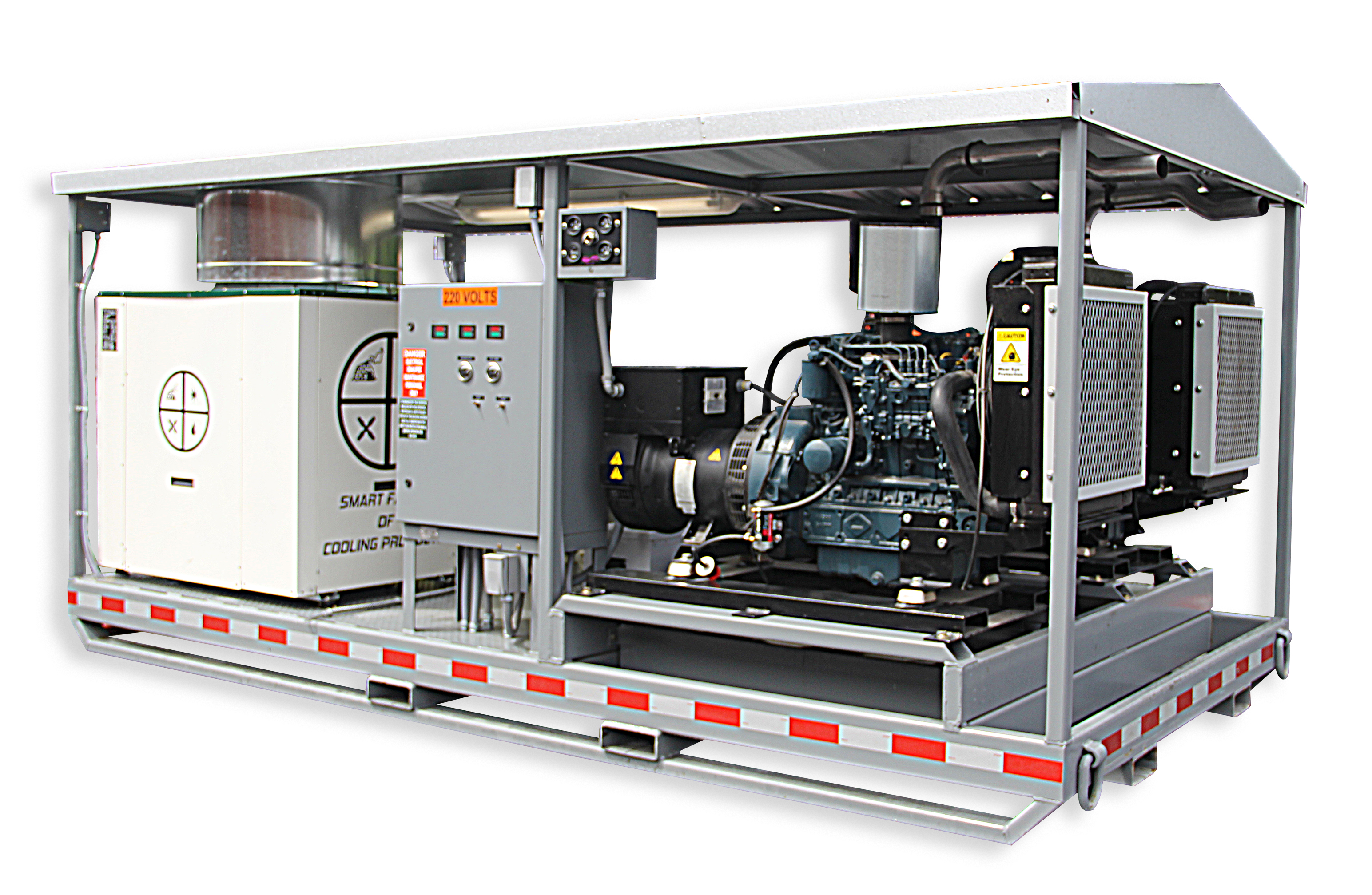

GeoKrete® Rig

Rehabilitate. Restore. Rebuild. The original large diameter geopolymer relining system, I-MARS Gen1 featuring the RMX-5000 mixer-pump is all you need to rehabilitate, restore or rebuild compromised infrastructure.

Seamless Rehabilitation Solution

I-MARS is a field-proven and reliable system that’s built to efficiently and effectively rehabilitate sewer infrastructure with the industry’s best geopolymer, Quadex® GeoKrete®. The I-MARS is an extremely versatile large diameter infrastructure rehab system and boasts a small footprint and exceptional mobility.

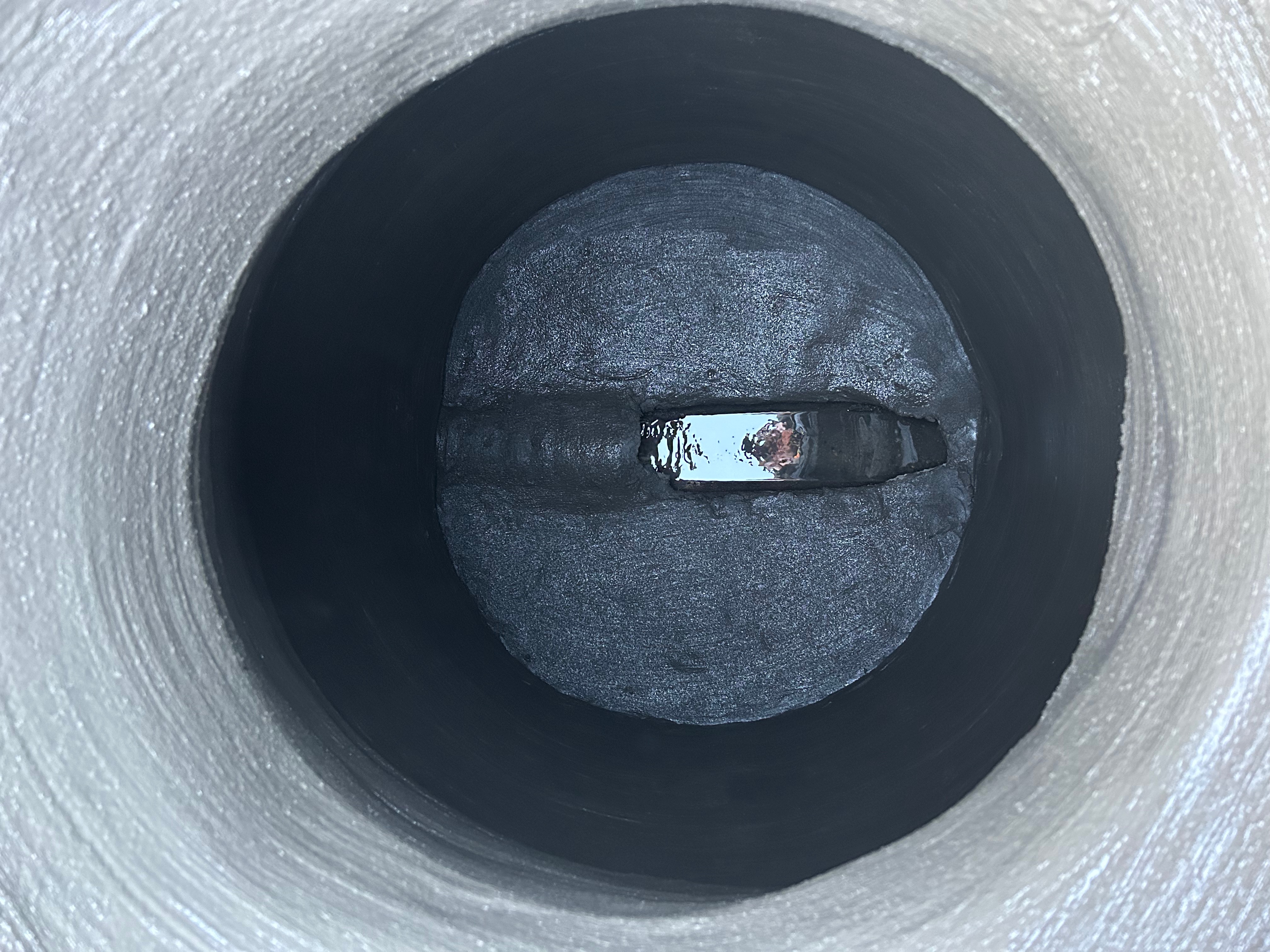

- Spin-cast, spray or trowel apply GeoKrete

- Restores large diameter structures of all shapes

- Pipe, tunnels, culverts, junction boxes, etc.

I-MARS System consisting of a compressor, generator, chiller, power and H2O distribution Gen1 RMX-5000 ultra-high pressure 3” | 76.2mm swing-tube, high sheer mixer and pump, custom-fabricated to apply GeoKrete Geopolymer.

I-MARS Powertrain Specifications

Compressor: 185 cfm rotary screw-type

Generator: 30 KW

Chiller: 4 ton | 3,629 kg

Water Tank: 225 gal | 852 L, Weight: 8.34 lbs/gal | 1kg/L

Dual Water Pumps: 110 gpm | 416.4 lpm

Dimensions: 160” L x 85” W x 81” H | 406.4 cm x 215.9 cm x 205.7 cm

Weight: 7,380 lbs | 3,348 kg

Fuel Capacity: 2 x 40 gal | 2 x 151.5 L tanks (empty)

RMX-5000 Mixer Specifications

Pump: 3” x 18” | 76.2 mm x 203.2 mm swing tube

Hydraulic Pressure: 3,000 psi | 206.8 bar

Face Pressure: 2,200 psi | 151.7 bar

Output: Up to 5 Cu-Yd/h

Mixer: 1,000 lb | 453.6 kg capacity

Hopper: Max 1,500 lb | 680.4 kg capacity

Engine: Yanmar Diesel, 65 hp, Tier 4 Final (Tier 5 EU)

Fuel Tank: 20 gal | 76 L (shipped empty)

Weight (Empty): 6,500 lbs | 2,948 kg

Dimensions: 152” L x 71” W x 69” H | 3.86 m x 1.80 m x 1.75 m

Trailer Mount: Optional

CE Certified: EU Market