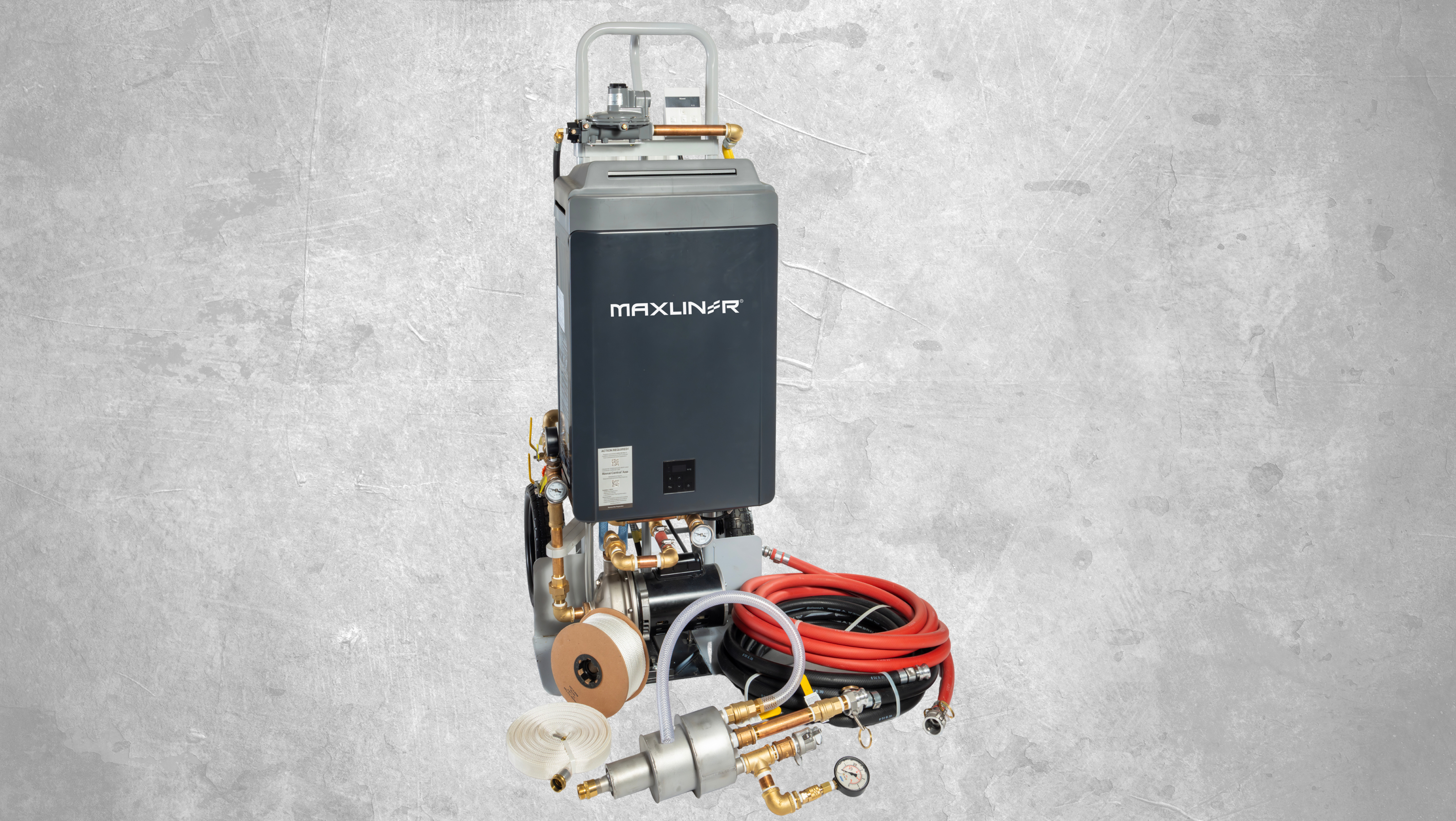

Inversion Drum for Liners Up to 6” | DN150

Max Length of 60 ft | 18m

The family of Max Inversion Drums allow you to easily, safely and quickly insert flexible liners into the sewer that needs to be rehabilitated. The resin-impregnated liner is wound onto the drum axle with a control rope and inverted into the open-ended or closed-ended sewer by compressed air. The inversion pressure and the inversion speed are constantly controlled via the control elements on the inversion drum.

After the impregnated liner has been inverted, the curing process of the liner can be accelerated with hot water, steam or UV/ LED light. This results in the creation of a new pipe in the old pipe.